News and media - press releases: 3D construction function as standard. New generation hydraulic excavator PIC 2000i-12 released.

Komatsu (President: Hiroyuki Ogawa) has fully remodeled its 20-ton hydraulic excavator, which is its main model in the civil engineering field, and will launch it on December 1 as the PC200i-12, a new-generation machine equipped with 3D machine guidance (hereinafter referred to as 3DMG)*l as standard. In addition, in response to the various ICT construction needs of customers, it is possible to switch to 3D machine control (hereinafter referred to as "3DMC")*2, and we will also start offering plans according to the level of use of 3DMC.

*1: 3D machine guidance: Design drawing data and information such as the position and attitude of the machine are displayed on the display of the driver's seat, allowing the operator to judge the drilling position relative to the design drawings.

*2: 3D machine control: When the operator operates, the machine automatically stops the machine and supports operations according to the drawings so that excavation can be done according to the design drawing data. Regardless of the skill of the operation, it is possible to construct according to the drawings.

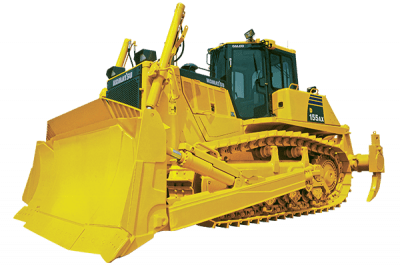

PC200i-12

In the construction industry, which is our customer, the issue of a shortage of future workers against the backdrop of a declining and aging population is becoming more serious. Since fiscal 2016, the Ministry of Land, Infrastructure, Transport and Tourism (MLIT) has been working on i-Construction to improve productivity in the construction industry, with a focus on ICT construction. This year, as i-Construction 2.0, a roadmap for labor-saving measures through automation of construction sites was presented, and ICT construction will be made a principle from FY2025 for earthworks and river dredging among the public works of the country, and the target types of work will be gradually expanded.

In 2014, Komatsu introduced hydraulic excavators equipped with machine control functions to the market as rental machines, and Smart Construction is a solution that visualizes and optimizes construction at construction sites using digital technology.®. ln 2015, we started to provide the service. To date, it has been installed at a total of more than 42,000 sites worldwide (as of the end of September 2024), contributing to the improvement of productivity at construction sites on both the axes of products (products) and solutions (experiences).

In the future, as the spread and expansion of ICT construction progresses, Komatsu will focus on smart construction, which is one of its strengths.®. At the same time, through the sale of the PC200i-12 equipped with 3DMG as standard, we will strongly support customers in the construction industry who support ICT construction in solving their problems, and aim to realize safe, productive, smart, and clean future workplaces together with our customers.

1. Accelerating integration with Smart Construction® through standard equipment of 3DMG Standard equipment of 3DMG

makes it easier for customers to introduce ICT construction. The guidance function displays bucket cutting edge information obtained from the machine's sensors and GNSS antennas on the monitor inside the cab together with 3D design data, contributing to reducing the number of staking and inspection work and assistants. Furthermore, by introducing the PC200i-12, you can also use the SmartConstruction® solution, which allows you to digitally centrally manage workers, vehicles, attachments, etc. at each site, visualize soil loading information, and draw on 3D design data. This will improve the efficiency of various operations such as vehicle dispatching, asset management, understanding the results of loading work, and considering temporary roads.

Now, the 3DMC usage plan can be switched by software, and a lump-sum payment plan or a pay-as-you-go plan is available depending on the customer's level of 3DMC usage. We will contribute to improving the productivity of our customers' worksites through detailed support according to the stage of their ICT construction response.

*3: A plan that can be used only with 3DMG is also available separately.

2. Main features of PC200i-12

(1) Workability, productivity, environmental friendliness

・By adopting a newly developed electronically controlled hydraulic system that realizes excellent fine operability with fine movements and improves work efficiency, and by installing a new engine with improved output (compliant with the 2014 regulations on exhaust gas from special motor vehicles), fuel efficiency has been improved by 20% compared to previous models. In addition, the work volume has been improved by 18% and the excavation force by 7%.

・Equipped with an automatic turning function that assists the loading work on the dump truck. It aims to semi-automate the loading work. In addition, upgraded payload function is standard equipment. It prevents insufficient loading and increases productivity on site. By adopting an expandable system, new functions can be provided and corrections can be made remotely by updating the software.

(2) Safety : The industry's first geofence function (3D)*4 that automatically prevents contact with electric wires and pipes at the construction site . When the vehicle moves, the re-setting of the work limit plane, which is necessary when controlling with 2D data, is no longer necessary by utilizing 3D data, which also contributes to improving safety and work efficiency. - Comes standard with the KomVision surrounding camera system that captures the surroundings of the machine in 360 degrees (previously 270 degrees) , and the KomVision collision detection brake system that warns and automatically slows down and stops the machine when it detects people or objects . It also has a fall detection alarm system that detects when the machine is in a position that is at risk of falling over, contributing to improved safety at the work site. *4: Geofence function (3D): A function that allows you to set a work limit plane that automatically stops the machine when it approaches.

(3) Comfort, operability, and maintainability: The newly designed wide cab has 30% more legroom than the previous model, and visibility has also been greatly improved.

・ The adoption of electric levers makes it easy to operate, and the touch panel monitor and various switches are ergonomically arranged close to the

operator's hand to reduce fatigue.

・The GNSS antenna is embedded in the vehicle body to prevent problems such as breakdowns caused by contact with obstacles and theft.

・The layout allows easy maintenance of inspection parts such as filters from the ground, and the replacement intervals for hydraulic oil and filters have been

extended to reduce maintenance costs.